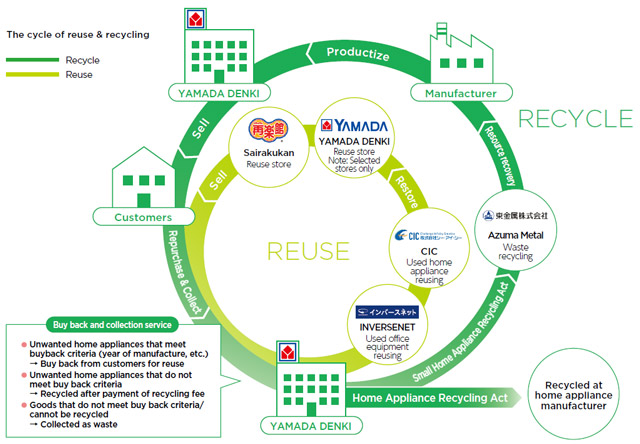

The YAMADA HOLDINGS Group, in line with its environmental policy, has helped to reduce its impact on the environment in society as a whole by completing the product life cycle within the Group. This has been done by constructing a system to reuse and recycle used electrical appliances collected from customers.

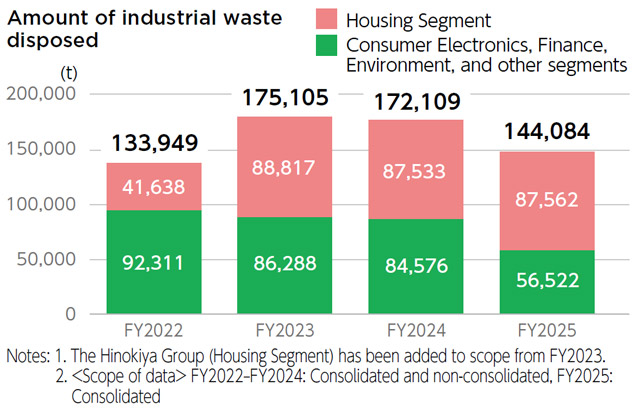

At YAMADA DENKI, in addition to the waste material generated from its stores, discarded home appliances from customers not covered by the Home Appliance Recycling Act are categorized into three groups: reuse, recycling, and disposal, in accordance with relevant laws, and are processed in a manner that supports waste reduction. The business of reuse, reducing waste and its proper disposal (recycling), and the utilization of resource recovery materials with a focus on home appliances is conducted under YAMADA Environmental Resources Development Holdings. The Company efficiently collects used products and reuses them wherever possible to resell and deliver on to customers. Additionally, in the Housing Segment, wood is pre-processed at factories for more efficient use of resources, and some of the packaging materials and waste generated from construction sites and demolition work are recycled, contributing to the reduction of industrial waste.

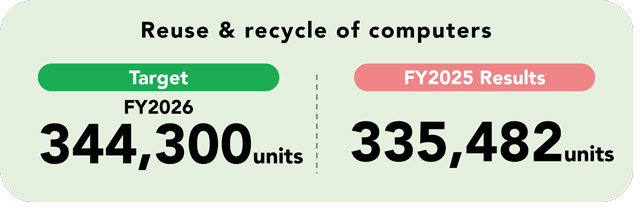

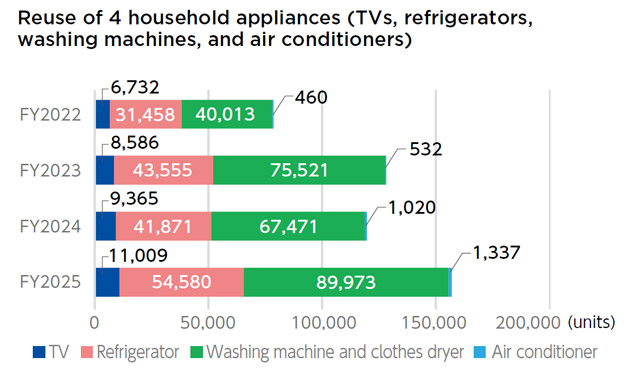

Our Group is building a complete distribution network for the reuse of home appliances, from the repurchase of quality products through to recycling and sales, centered on CIC which develops environmental resources. Our reuse centers provide a service that allows customers to purchase reused home appliances with peace of mind by giving every product we buy back in our stores a thorough functional check, cleaning, and repair, as well as a warranty of up to 24 months from the day the product is purchased. As for the reuse of computers, INVERSENET recovers secondhand computers for resale.

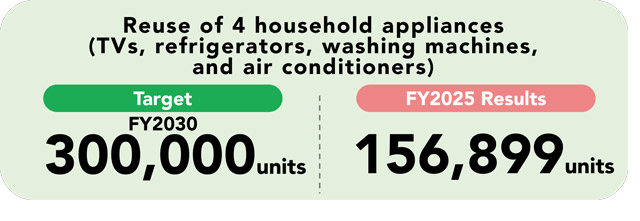

In May 2022, the YAMADA East Japan Reuse Center Gunma Plant was expanded with the aim of increasing production of reused products. The Gunma Plant has introduced automated warehouses that store various used home appliances sent from all over the country, as well as an automatic washer for washing machine drums, strengthening its initiatives.

In addition, the newly-built Yamaguchi Plant began operations in June 2025 with the goal of increasing production and reducing CO2 in western Japan by shortening product transportation distances to the Chugoku, Shikoku, and Kyushu regions. Toward the production of 300,000 units for FY2030, we will continue to leverage our advanced technological capabilities to promote the establishment of a circular resource system and aim to expand the productivity of reused products.

The new YAMADA West Japan Reuse Center Yamaguchi Plant

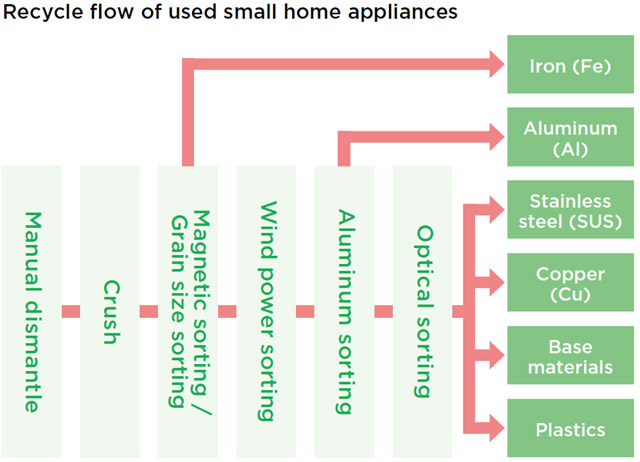

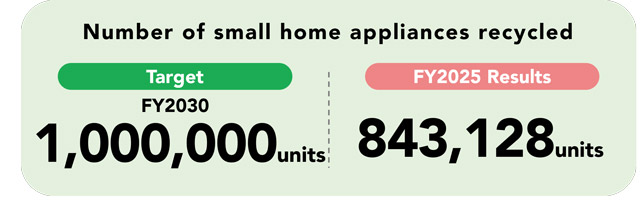

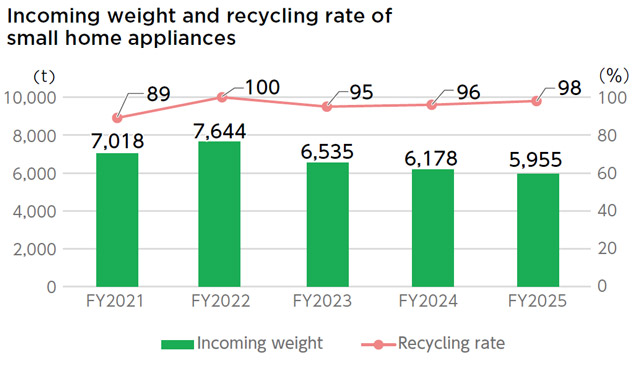

We collect used small home appliances that don’t meet the reuse criteria but can be recycled at our YAMADA DENKI stores based on the Act on Promotion of Recycling of Small Waste Electrical and Electronic Equipment (Small Home Appliance Recycling Act*).

Collected small home appliances are meticulously sorted at the recycling plant within the Group (Azuma Metal) and separated into component materials such as iron, aluminum, stainless steel, and plastics, which are then reused as raw materials in various products.

Going forward, we will further increase the number of products that can be recycled by building systems and using machines with advanced sorting functions, leading to a reduction in waste.

*A law that encourages the formation of a circular economy whereby a government-certified business operator collects and processes electrical machinery and appliances, excluding the four categories of home appliances subject to the Home Appliance Recycling Act (TVs, air conditioners, refrigerators and freezers, and washing machines and clothes dryers).

We also develop and sell eco-friendly products utilizing resource recovery materials from recyclable items. Recycled plastics are utilized in pallets for reuse plants, shopping baskets in stores, and carry handles for small home appliances, contributing to sustainable initiatives. In the future, the Group will aim to develop and sell products in various fields such as housing.

Pallets at the Reuse Fujioka Plant

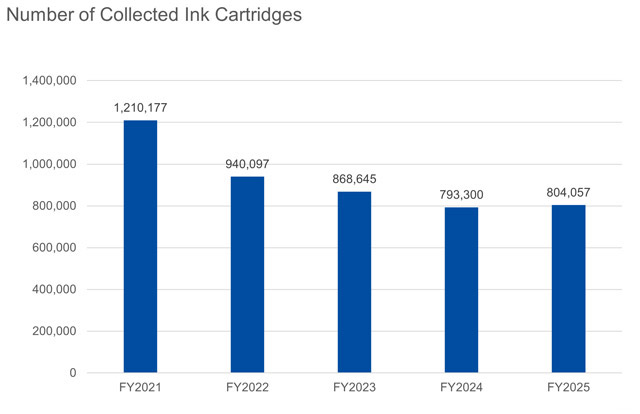

YAMADA DENKI donates 10 yen for every used ink cartridge deposited at one of its reusable ink cartridge collection boxes in each of its stores. In the fiscal year ended March 2025, approximately 0.8 million cartridges were collected with 8,422,421 yen donated to the Foundation for Orphans from Automobile Accident. The amount of carbon emissions was also reduced by 66t through the collection and sale of ink cartridges.

Since February 2020, YAMADA DENKI has been using electronic shelf labels (electronic prices) for its digital home appliances. Electronic pricing not only reduces the amount of paper and ink used, but also helps to streamline inventory management and reduces workloads for employees.

Electronic Shelf Labels (electronic prices)

Our Group manages water treatment properly during the reuse process in environmental projects, striving to conserve water resources by reducing water usage through recycling and other means. Our reuse production plants consume approximately 30,000 m³ of water annually. Our automatic washing tub cleaners adopt a recycling system that filters and reuses hot water without using detergents. Hypochlorous acid water is used for refrigerator disinfection, aiming to reduce environmental impact. We will continue to focus on water resources initiatives, working to maintain and manage the natural environment to preserve biodiversity.

Housetec, which has housing and environmental equipment as one of its core businesses, is engaged in the water environment business and is focusing on the development and sale of septic tanks. The installation of septic tanks for new home builds is stipulated in law in Japan (excluding planned sewerage treatment areas). As such, single-type septic tanks that handle only wastewater from toilets, and combined-type septic tanks that treat all domestic wastewater, including from the kitchen and bathroom, have become widely used. The revised septic tank law that came into effect in 2020 encourages existing singletype septic tanks to be converted into combinedtype tanks. The combined septic tank developed by Housetec is designed to replace single septic tanks, achieving space efficiency. In addition to its energy-efficient design, it uses lightweight and highly durable DCPD* resin, providing strong resistance to disasters such as earthquakes, with a proven track record of installation in various locations. Our Group companies, Nikka Maintenance and Chubu Nikka Service, are involved in the maintenance, inspection, and installation of septic tanks, supporting our customers’ living environments. We will continue to focus on the development, dissemination, and maintenance of environmentally friendly septic tanks, aiming to further improve water environments and promote biodiversity through water conservation efforts.

*DCPD: Dicyclopentadiene